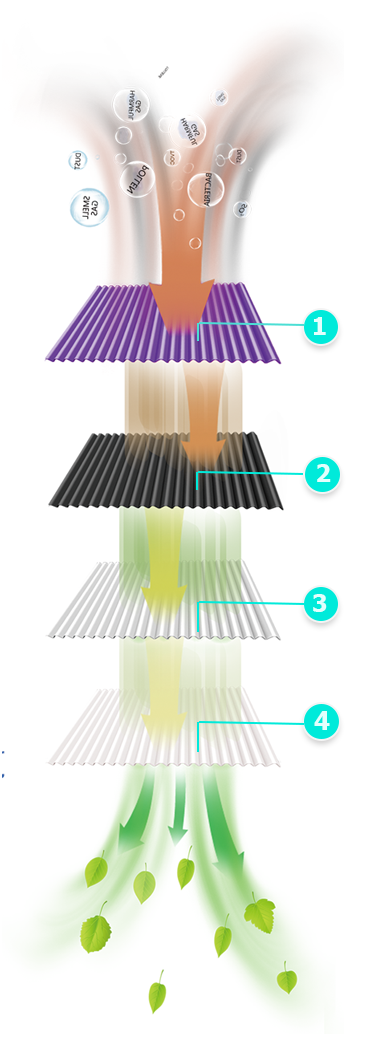

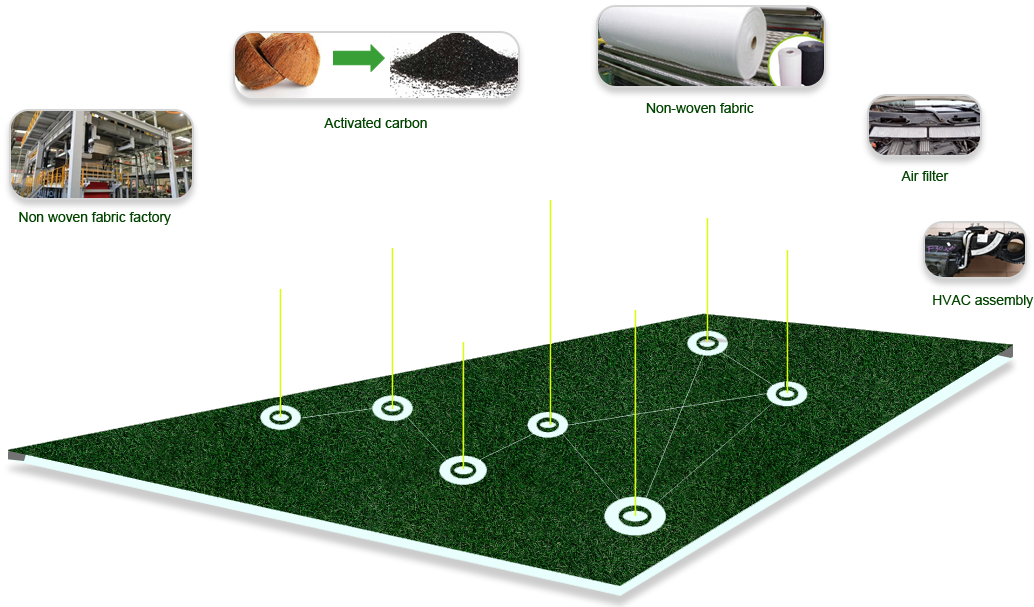

Lesha filters meet relevant industry standards and requirements, ensuring that its filters meets all customer needs and wants whether it be at the OEM level or aftermarket levels.. Lesha fully considers the flux capacity of the core filter in product design, ensuring that the filter element can operate stably and provide sufficient filtration speed under the specified pressure difference. The selection of filter element materials are determined to meet the filter's high filtration efficiency, with sufficient strength, good chemical stability, and wear resistance.

The raw materials of activated carbon filter products are tested in a timely manner according to different activated carbon materials before processing. Based on the physical properties of different activated carbon, the machine is adjusted to ensure that the original characteristics of activated carbon will not be changed during processing.

OE Sample

Housing Installation

Media Performance Database

OEM/OES Performance Comparison

Project Development

Product Development

Raw Material Development

Laboratory/IE

Total 1600 part number

90% European, 90% American, 80% Japanese and 70% Korean for share of car application

Product development covering Light Duty, Heavy Duty and Electrocar area